Essential Considerations for Guaranteeing Top Quality and Long Life in operation Engines

When thinking about the acquisition of a made use of engine, ensuring its quality and longevity needs a diverse method. Maintenance background is an essential aspect, as it gives insight into the engine's past care and possible future integrity. Efficiency testing is likewise essential, using a snapshot of the engine's functional performance.

Engine History Assessment

In the realm of utilized engines, a detailed engine history examination is extremely important to guaranteeing quality and reliability. Recognizing an engine's past can provide important understandings right into its performance capacities and prospective future long life. A meticulous background review encompasses numerous crucial elements that play a significant role in assessing an engine's problem. First of all, upkeep records are important. Normal maintenance, including oil modifications, filter replacements, and set up tune-ups, show that the engine has been well-cared-for, decreasing the likelihood of unexpected failings.

Engines that have gone through considerable repairs may have underlying concerns that might resurface. Checking out the engine's gas mileage can serve as a sign of wear and tear. An engine utilized mostly for long-distance highway driving may be in far better condition than one subjected to constant stop-and-go city website traffic.

Basically, an exhaustive investigation right into an engine's background is vital for making enlightened purchasing choices. used engines for sale.

Comprehensive Evaluation Overview

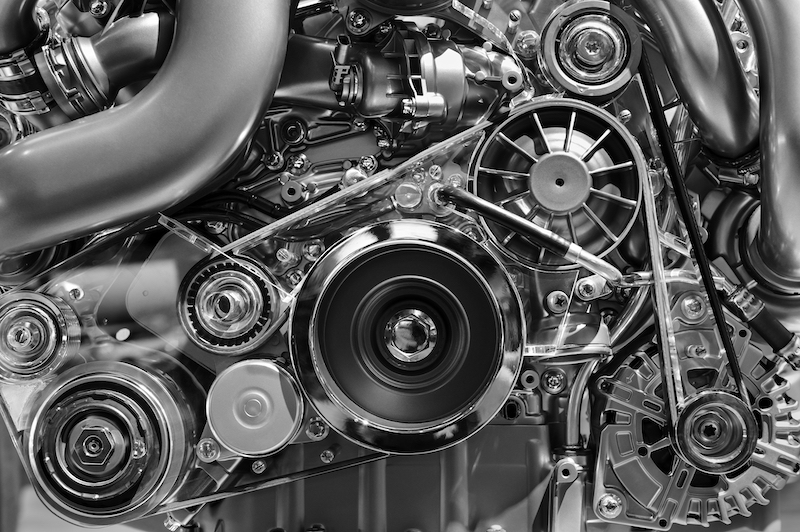

While comprehending an engine's history supplies useful context, an extensive examination is the next step to guarantee its present problem straightens with historic data. The inspection must start with a visual evaluation, looking for indications of leakages, deterioration, and uncommon wear. Evaluate the exterior for oil discolorations or coolant marks, which might show underlying issues.

Next, examine the engine's placing system for any kind of loosened screws or irregularities that might influence performance. Pay attention to the condition of belts and tubes, as these elements are essential for optimal engine capability. Check out for fractures, fraying, or any signs of wear and tear.

Recognizing Damage

Identifying indications of wear and tear is essential for examining an utilized engine's long life and integrity. It involves a precise examination of numerous engine parts to determine their existing state and potential future efficiency.

Another critical element is evaluating the engine's seals and gaskets. In addition, irregular noises during engine procedure, such as knocking or ticking audios, might show interior damages or extreme wear on relocating parts like Click This Link pistons or bearings.

The condition of belts and hose pipes is similarly important, as they play an essential role in the engine's general function. Cracked or torn belts and brittle hoses are indicators old that can result in engine failure if ignored. Finally, checking out the oil condition and filter can supply insights into previous maintenance practices, as unclean oil or stopped up filters recommend disregard and increased wear.

Performance Screening Fundamentals

Assessing the damage of engine components sets the stage for a thorough evaluation via performance screening. Efficiency screening works as a vital step in establishing the functional honesty of a made use of engine. By replicating real-world conditions, it evaluates the engine's ability to supply power efficiently and reliably. Trick metrics include horsepower, torque, gas effectiveness, and exhausts levels. This data supplies useful insights right into the engine's present efficiency and helps determine prospective concerns that might not be quickly visible.

Using dynamometers is a common method in efficiency screening. These tools gauge the engine's result across numerous conditions, using a detailed profile of its capability. Additionally, on-road screening enhances dynamometer evaluations by observing engine behavior under common driving scenarios, guaranteeing it read review fulfills the called for criteria for both security and efficiency.

These devices analyze engine monitoring systems, recognizing faults in electronic components that could influence efficiency. Comprehensive screening not only confirms the engine's operational status but likewise aids in forecasting future maintenance demands.

Maintenance and Care Tips

Appropriate upkeep and care are crucial to extending the life-span of a used engine and guaranteeing its constant performance. Regular oil adjustments are critical; making use of the maker's advised oil kind and grade can avoid excessive damage. Furthermore, oil filters find more info ought to be changed concurrently to keep optimal lubrication and tidiness within the engine.

Monitoring fluid levels, including coolant, transmission fluid, and brake fluid, is vital. Making sure these fluids are at proper degrees aids avoid getting too hot and other mechanical concerns. Inspecting belts and pipes for indications of wear, such as fractures or fraying, can avert potential failures that may lead to pricey repair services.

Routine examination of the air filter is additionally essential, as a clean filter makes certain efficient air movement and combustion, thus maximizing engine efficiency. Stimulate plugs should be inspected and replaced when needed to preserve reliable fuel burning and protect against engine misfires.

Last but not least, regular diagnostic checks utilizing professional devices can determine potential concerns prior to they become substantial problems. By adhering to these upkeep and care pointers, made use of engine owners can guarantee their engines stay reliable, effective, and with the ability of executing more than a prolonged period.

Conclusion